Workers Compensation Specialists

What are “Experience Mods”?

What are “Experience Mods”?

The key to understanding your workers’ compensation premium is the “Experience Modification Factor”, also known as your “Mod”. Understanding your company’s mod and the data used to calculate it helps you identify ways to minimize your workers’ compensation premium.

What does your mod reveal?

While the mod itself is a single number, an analysis of how your payroll and loss data functions in the experience rating formula can provide valuable insight.

Mod calculation varies by state but generally depends on these components:

- Actual losses from the three prior policy periods, not including the most recent policy period

- Expected losses based on payroll and expected loss rates for the industry

- The amount of each loss, i.e., its severity

- Whether the loss is medical-only, without wage loss payments

- Ballast and weighting values published by the National Council on Compensation Insurance (NCCI)

There is a great deal more to Workers’ Compensation Insurance than price. Let us show you how to use “Mod” analysis to identify problem areas, improve safety and decrease your premiums.

Here are 10 tips to help you impact your bottom line.

- Investigate accidents immediately and thoroughly; take corrective action to eliminate hazards, and be aware of fraud.

- Report all claims to your carrier immediately. Alert the carrier to any serious, potentially serious or suspect claims. Frequently monitor the status of the claim, and communicate with the adjuster to resolve them as quickly as possible.

- Take an aggressive approach to providing light duty to all injured employees upon their release from treatment. Supervise light duty employees to ensure their conformance with restrictions.

- In serious cases that involve lost time, communicate with the claims adjuster to demonstrate your interest in returning the injured employee back to gainful employment.

- Set safety performance goals for those with supervisory responsibility. Success in achieving safety goals should be used as one measure during performance appraisals.

- Develop a written safety program, and train employees in their responsibilities for safety. Incorporate a disciplinary policy into the program that holds employees accountable for breaking rules or rewards them for correctly following safety procedures.

- Frequently communicate with employees, both formally and informally, regarding the importance of safety.

- Make safety a priority – senior management must be visible in the safety effort and must support improvement.

- Evaluate accident history and near-misses at least monthly. Look for trends in experience, and take corrective action on the worst problems first.

- Hire Eastern Michigan Agencies to ensure success.

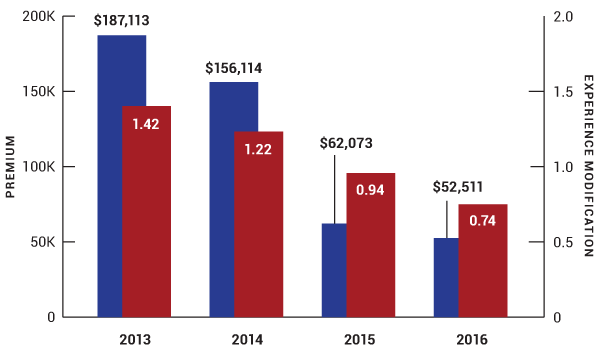

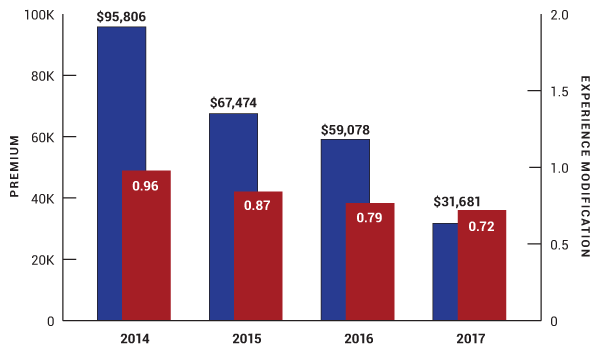

Numbers on typical cost savings:

Automotive Interior Systems Manufacturing

Steel Processing Company